Did you know that a single industrial machine can outperform hundreds of human workers? That's right; the sheer power of these machines is revolutionizing industries as we know them. But why exactly is this transformation happening now?

In today's rapidly evolving economy, the pressure on manufacturers to boost efficiency and output has never been higher. The spotlight is on cutting-edge technology, and the stakes couldn't be higher.

Here’s the surprising bit: these machines don’t just replace traditional labor; they redefine it. A factory can essentially operate in near-total darkness with machines that can run 24/7 without breaks or complaints. This new era isn't just about doing things faster — it’s about redefining what’s possible. And while traditional craftsmanship still holds value, it’s undeniable that automation is rewriting the rules of production. But that’s not even the wildest part…

What if I told you that some industrial machines are now capable of self-maintenance, predicting when they need repairs before they break down? This predictive technology not only saves time and money but also sets the stage for a future where unscheduled downtime is virtually eliminated. Imagine the potential to save billions annually on repair costs — it's closer than you think. What happens next shocked even the experts…

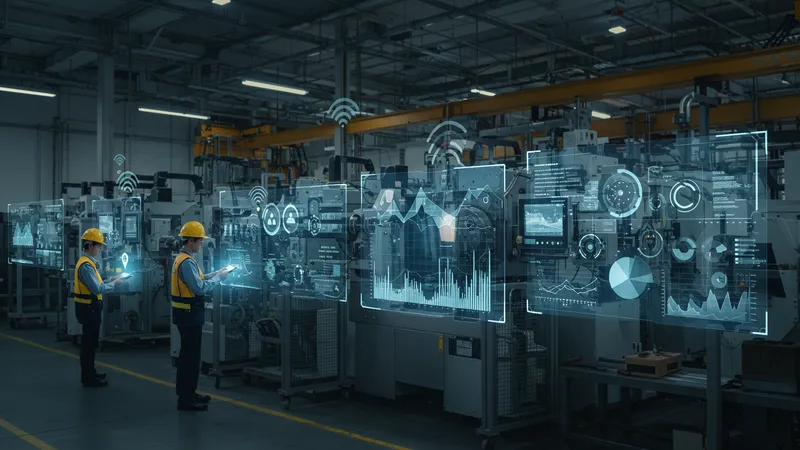

Smart factories are becoming a cornerstone of modern manufacturing. These facilities leverage interconnected machines that communicate with each other through the Internet of Things (IoT). It turns out that these factories can detect issues before they happen, thanks to real-time data analytics. This proactive approach means fewer disruptions and a seamless flow of operations. But there’s one more twist: these smart factories can even learn and adapt over time!

This evolution dramatically reduces human error and leads to unprecedented levels of productivity and precision. Imagine a world where factories complete tasks with 99.9% accuracy consistently. The ramifications are huge, affecting everything from product quality to customer satisfaction. But the power of smart factories doesn't stop there.

There are insider tips shared by industry leaders about integrating these technologies successfully. For one, implementing pilot phases and employing a step-by-step integration process is crucial. This allows for troubleshooting and adjustment without halting production. Yet, the exciting bit is the collaborative robot technology—robots working side-by-side with humans, streamlining complicated tasks. What you read next might change how you view industrial innovation forever.

Through smart automation, companies are not just surviving but thriving amidst global competition. It’s fascinating how dynamic algorithms can adjust operations for peak efficiency while minimizing resource waste. The potential savings and increases in output are substantial, and this model is pushing businesses to rethink their strategies fundamentally.

You might think industrial machines would be environmentally detrimental, but the reality is quite the opposite. Many companies are adopting green technologies that drastically cut emissions. One significant advancement is energy-efficient machinery that operates cleaner than its predecessors. In fact, some systems recycle heat generated during production, vastly improving energy efficiency. But there’s more to the green machine movement.

Sustainable manufacturing practices are being implemented across industries. For instance, closed-loop water systems are reducing water waste dramatically. A beverage plant recently cut its water use by 80% thanks to intelligent resource management systems. This change is more critical than ever, as global climate crises require swift adaptation by major players in the industrial sector.

Even though some argue it’s not enough, the strides being made are undeniable. These sustainable practices aren’t just reducing footprints; they’re also attracting investors looking to build ethical portfolios. What you read next may alter your perception of what industry can achieve environmentally.

But it’s not merely about environmental goodwill; these technological shifts have economic incentives. Reducing waste means reducing costs, translating into better margins. In a fascinating twist, it also creates a competitive edge, appealing to conscious consumers who are selective about whom they purchase from. But the hidden benefits of this approach are just beginning to unfold.

Amidst the technological glow, the human element still shines brightly. Machines don’t replace jobs; they change them. The future of manufacturing is about collaboration between humans and machines, a partnership where each leverages their strengths for unprecedented outcomes. Consider factories where AI interfaces guide workers step-by-step through tasks, reducing training time and error rates.

But the most impressive bit might be how these machines are enabling creativity. Human workers have more time for innovation since machines handle repetitive tasks. This shift allows workers to focus on design improvements and new product development—areas that machines can’t yet master. It’s an unexpected outcome, merging tech with the human touch.

Training programs are also evolving. On-the-job training happens augmented by virtual reality, allowing newcomers to experience real-world scenarios in a safe, controlled environment. This method not only speeds up learning but also significantly improves skill retention. What you read next might redefine how we consider education and skill development.

The most significant advantage of this symbiosis might be job satisfaction. Workers in technologically advanced settings report higher job satisfaction rates than their counterparts, thanks to reduced monotony and increased problem-solving tasks. This human-machine synergy may very well be the key to a balanced and prosperous future in industrial domains.

The shift to automated industries isn't just technological; it's transforming business models too. Consider service-based approaches like Equipment-as-a-Service (EaaS). Customers no longer purchase machinery outright; instead, they pay for usage and outcomes, akin to software subscriptions. This model reduces upfront costs and aligns more closely with modern business needs, making it a win-win scenario.

Companies embracing this model are seeing rapid growth. Predictive maintenance services can be bundled with machinery, offering comprehensive solutions that guarantee operational efficiency. But it's the flexibility for scalability that truly sets this model apart. Businesses can effortlessly scale operations to meet demand without being bogged down by capital expenditure restraints.

What's more, these adaptive business models come with a community spirit. Forums and networks connect users, allowing them to share tips and experiences, enhancing everyone’s ability to make smarter, data-driven decisions. This cooperative dynamic builds a support system that’s organic and more effective than traditional customer service.

Yet another surprise is the collaboration between companies and educational institutions. Tailored courses are developed to ensure students are graduating with relevant skills to fill the emerging roles brought about by these new models. It’s a paradigm shift in how industries interact with academia, ensuring a future-ready workforce.

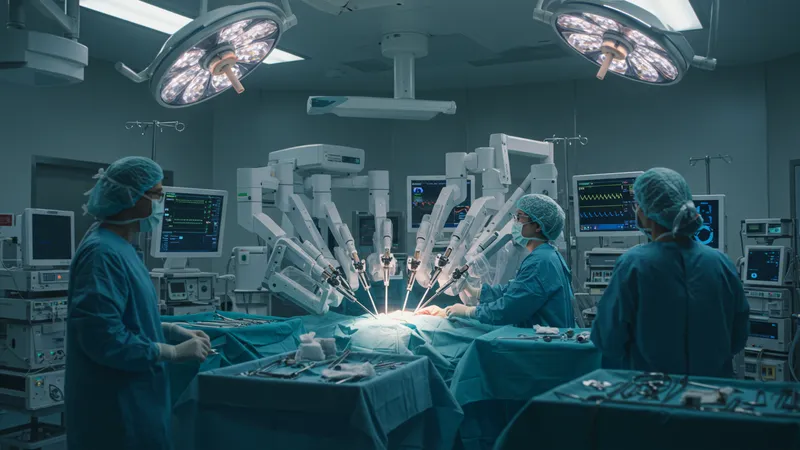

It might surprise you to learn that industrial machines are making significant inroads in healthcare. Advanced robotics is used in surgeries, ensuring precision that was once unattainable. Hospitals are now outfitted with machinery that assists in patient care, from automated diagnostics to maintaining sterility in surgical environments. But the scope of this integration doesn’t stop there.

The production of pharmaceuticals has also seen the benefits of advanced machinery. Machines ensure precision, consistency, and speed in drug manufacturing processes that human hands find difficult to match. This efficiency means that life-saving medications reach the market faster, delivering hope to patients sooner than ever before.

But beyond production is the revolutionary potential for real-time patient data analysis. Machines are now assisting in monitoring patient vitals, predicting complications before they can escalate. This capability is reshaping how hospitals operate, shifting from reactive to proactive care, saving countless lives through timely interventions.

Moreover, the reliability of machines ensures that tasks that require intensive labor, such as data entry, are handled with utmost accuracy, reducing workload on healthcare professionals. This means more time for human-patient interactions, something that even the most advanced machine can't replace. But this human-machine partnership in healthcare is just the beginning of a new medical revolution.

In construction, industrial machines have already revolutionized how infrastructure projects are executed. These machines are capable of performing tasks with unprecedented speed and accuracy, from laying bricks with robotic arms to autonomous bulldozers leveling sites. The precision offered reduces material waste, which is both cost-efficient and environmentally friendly.

One unexpected advancement is the advent of drone technology for site assessments and project management. These drones can map large areas in minutes, providing data essential for strategic planning. Through this, site managers can make informed decisions, enhancing efficiency and safety standards.

The role of 3D printing cannot be overstated in modern construction, as this technology allows the creation of structural components with little material waste and improved timelines. Imagine a world where affordable, sustainable housing solutions can be quickly produced during crises or shortages, and it's unfolding right now!

In this constantly evolving landscape, the collaboration between robotics and automation is forging new ways to tackle urban development challenges. But the true marvel might be in the seamless integration of these technologies, setting the stage for smart city concepts, where infrastructure responds dynamically to its inhabitants’ needs.

Imagine a world where machine maintenance is no longer a reactive, but a predictive, systematic discipline. Thanks to artificial intelligence and IoT, industrial maintenance is undergoing a revolutionary transformation. The proactive nature of modern maintenance reduces unexpected downtimes and keeps the industrial giants rolling smoothly.

Sensors now track the health of machinery in real-time, allowing predictive analytics to foresee failures before they occur. Not only does this reduce operational disruptions, but it also significantly decreases maintenance costs as parts are replaced before damage can escalate.

Technicians armed with augmented reality glasses can perceive machinery in ways that were impossible before, overlaying digital information to identify issues swiftly without time-consuming disassembly. This technology reduces repair time significantly, dramatically raising the productivity of maintenance teams.

As technology progresses, the barrier between digital and physical continues to shrink. The future of maintenance is not only practical but also exciting, paving the way for even more advanced and integrated systems. Imagine. The evolution of industrial maintenance might just redefine the entire landscape of manufacturing.

Despite the myths, the rise of industrial machines isn't leading to mass unemployment but is reshaping jobs for the better. Workers are moving into more skilled, tech-driven roles. Instead of being replaced, they’re being equipped with new tools and responsibilities, fostering a workforce ready for the digital era.

This transition is causing old perceptions to shift. Where once a manufacturing job was seen as monotonous and unskilled, it is now becoming a respected, advanced career choice. With robotics handling repetitive tasks, human workers are focusing more on oversight, management, and strategic development.

Reskilling and upskilling initiatives are growing, with programs funded by governments and corporations. These initiatives teach workers crucial skills like programming and data analysis, ensuring they contribute to the industry’s growth and future direction. It’s a concerted effort to empower a workforce for tomorrow’s challenges.

But perhaps what’s most surprising is the rise of hybrid jobs combining digital expertise with traditional craftsmanship. These roles are not only more fulfilling but also exhibit the adaptability and ingenuity of the human spirit in the face of change. This reimagination of manufacturing jobs marks a new dawn in the industrial age.

Industrial machines are not limited to factories but have profound effects on supply chains nationwide. Through intelligent logistic systems, entire supply chains can be automated and optimized for precision and speed. This definitely reshapes how goods reach consumers quickly and efficiently.

Robotic systems handle everything from sorting to package dispatching. In addition, automated warehouses use innovative vertical storage and retrieval solutions to maximize space and reduce retrieval times. These innovations are speeding up processes that took days, now completed in hours or less.

The incorporation of AI into logistics management is another game-changer. This technology projects demand with astonishing accuracy, allowing companies to align production with market needs, minimizing waste, and ensuring that inventory levels match consumer demand, allowing responsiveness to market fluctuations.

The synergy between advanced machines and logistics proves that the future of supply chains is data-driven and incredibly agile. The surprises don’t end here, but rather herald a new standard of efficiency and service in global commerce.

The intersection of industrial machines and the energy sector is yielding groundbreaking results. Through advanced drilling equipment and automated oil platforms, energy companies are tapping into reserves with precision and safety unheard of a decade ago.

This tech revolution is expanding into renewable energies. Machines now harness wind and solar power more efficiently, optimizing placement and maintenance. This indicates a scalable path towards a sustainable energy future, impacting every facet of energy production and consumption.

However, it’s in operational safety that innovations are most pronounced. Drones and AI now closely monitor facilities, identifying potential hazards before they escalate into damaging incidents. The implications of this on environmental protection and regulatory compliance are enormous.

Even so, the convergence between traditional energy industries and modern technology is striking. It is setting the path toward greener and more efficient energy production, a vital step in addressing the global energy demands responsibly.

The marriage of industrial machines and agriculture is set to transform how we produce food. Automation is no longer confined to machines in factories; autonomous tractors and harvesters are taking over fields, dramatically increasing production yields and efficiency.

One cutting-edge technique involves precision farming tools that reduce the use of fertilizers and pesticides by deploying them only when necessary, based on real-time data. This innovation is making agriculture more sustainable and less resource-intensive.

Vertical farming harnessing robotics and controlled environments is set to change urban food production dynamics, allowing for fresh produce all year round with diminished land and water use. These systems are turning agriculture upside down in cities worldwide.

The most promises are hidden in genetic innovation facilitated by machine-driven analytics and sequencing. These innovations could hold the key to drought-resistant crops, paving the way toward feeding an increasing world population with the sustainable tools provided by industrial advances.

Autonomous industrial machines proliferate beyond factories, paving the path for a new transportation era. Self-driving trucks promise safer and efficient long-haul journeys. This innovation alone has the potential to transform logistics and the landscape of long-distance freight.

Urban areas, too, see benefits from automation in public transport, with self-driving buses testing routes in forward-thinking cities. The seamless integration of shared and autonomous transport could redefine urban travel, enhancing access and reducing congestion.

The automotive industry harnessing AI and robotics in production lines has streamlined production while fostering higher-quality, more personalized vehicles. The precision and customizability available to modern manufacturers are unmatched.

What’s unfolding goes beyond today’s imagination, promising safer, cleaner, and efficient transport just around the corner. The continued fusion of intelligent machines and transport offers a glimpse of a future where travel seamlessly connects with our daily routine, forever changing our perception and experience of mobility.

The aerospace sector thrives on precision, where failure isn’t an option. Enter industrial machines - the harbingers of enhanced manufacturing techniques refining aircraft production, ensuring remarkable accuracy and dependability beyond human capability.

One groundbreaking development is 3D-printed components, a revolutionary shift providing incredible strength while reducing weight. This leap means lighter, more fuel-efficient aircraft, fundamentally transforming this venerable industry.

In another surprising twist, machines handle quality assurance with precision, using AI-driven analytics to detect defects invisible to the naked eye, protecting passengers and crew alike. This certainty is pivotal in an industry defined by exacting standards and safety regulations.

Even in maintenance, smart sensors and drones are dispatching engineers only when genuinely necessary, far improving cost efficiency and turnaround times. The ongoing evolution of aerospace promises minimal wastage and maximum performance in getting people and goods off the ground.

Amidst the bytes and algorithms, industrial machines breathe physical life into fintech. ATM service networks and payment processing hardware continuously evolve, aligning with the digital economy's needs seamlessly, a backbone supporting billions of transactions daily.

These machines boost efficiency beyond financial hubs, impacting everyday lives with remarkable efficiency. They act as the tangible enablers in an increasingly cashless age, where seamless, secure transactions are paramount.

Inside terminals, industrial machines authenticate transactions leveraging biometrics systems and advanced encryption. This convergence ensures fraud prevention is ever sophisticated, keeping financial transactions secure across the globe.

The robust blend of industrial machines and fintech shapes the future financial landscape, exhibiting the intertwined network of digital innovation and tangible machinery that powers an economy endlessly evolving yet steadfastly reliant on the most advanced tools humanity can offer.

The integration of industrial machines into various sectors has sparked a revolution characterized by speed, efficiency, and sustainability. As industries embrace robotic and automated solutions, production becomes cost-effective and environmentally sound, enhancing day-to-day operations and future pathways. However, the full extent of this transformation is yet to unfold, creating uncharted opportunities and challenges. Bookmark this evolving narrative or share it with those curious about industrial machines’ transformative potential—they’ll want a front-row seat to what's reshaping our world.